PTFE Hydraulic Seals

PTFE Poly-Tetra-Fluoro-Ethylene is a synthetic fluoropolymer of tetrafluoroethylene. PTFE is well-known for its non-sticky, non-wetting and low-friction properties. Due to its excellent chemical resistance, PTFE is widely used in various applications, such as hydraulic seals, gaskets, bearings, electrical insulators, and more.

PTFE hydraulic seals are widely used in hydraulic systems due to its superior performance over traditional seals such as Nitrile Rubber, Viton, etc. PTFE seals can endure pressure of up to 12,000 psi and temperatures ranging from -190C to 260C. They are compatible with most of the hydraulic fluids like petroleum oil, synthetic oil, water glycol, and more. PTFE seals are particularly preferred in high-speed, high-pressure, and high-temperature applications where superior performance is required.

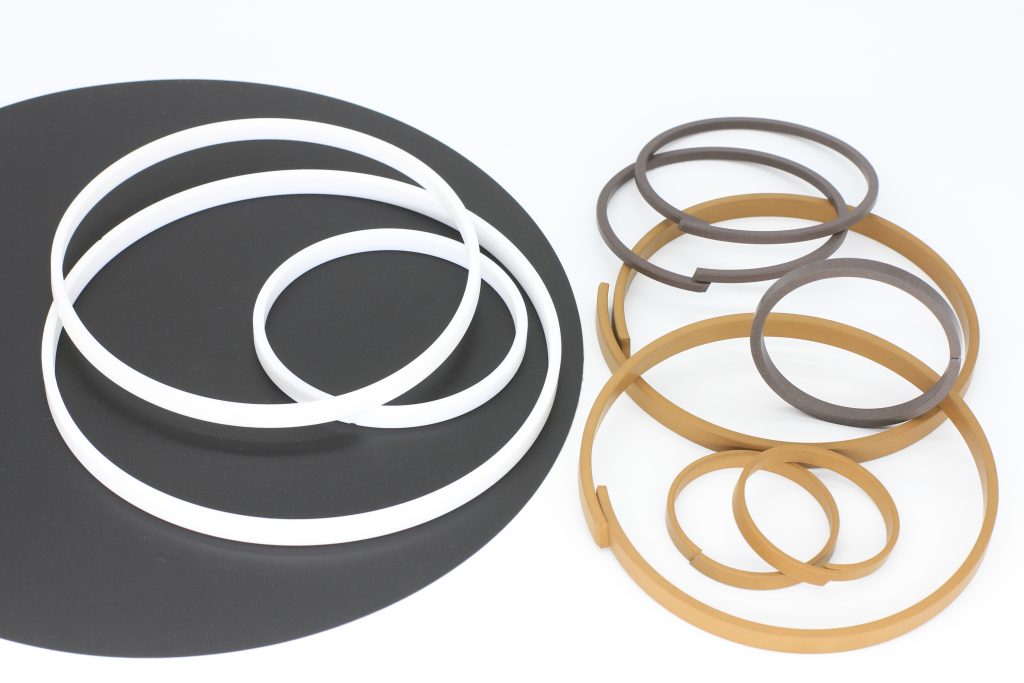

PTFE seals can be custom-designed to suit specific application requirements. They are available in a variety of designs such as rod seals, piston seals, wipers, and more. One of the most common forms of PTFE seals is the PTFE envelope seal, also known as PTFE shaft seal or PTFE lip seal.

PTFE envelope seals consist of a PTFE ring with an elastomeric core. The PTFE ring provides low-friction and chemical resistance while the elastomeric core provides flexibility and resilience. PTFE envelope seals are particularly suitable for applications where high-speeds, high-pressure and aggressive media are present. They are often used in hydraulic cylinders, pumps, motors, and valves.

PTFE hydraulic seals offer exceptional performance and durability in high-pressure, high-speed, and high-temperature hydraulic applications. They are highly customizable and provide superior chemical resistance and low-friction properties. PTFE envelope seals are a common type of PTFE seal that is widely used in hydraulic cylinders, pumps, motors, and valves.